Advantages of Digital Truck Scales Over Analog Truck Scales

In the transportation and logistics industry, truck scales are vital tools for accurately measuring the weight of vehicles and their loads. While traditional analog truck scales have been in use for decades, digital truck scales are rapidly gaining popularity due to their improved accuracy, efficiency, and advanced features. In this article, we will explore five significant advantages that digital truck scales have over their analog counterparts.

2. Real-Time Data and Integration Capabilities

Another key advantage of digital truck scales is their ability to provide real-time data and integrate with various management systems. Unlike analog scales, which typically require manual reading and recording, digital scales offer instant weight data that can be automatically transmitted to central systems for processing and analysis. This real-time capability reduces human error, speeds up operations, and provides valuable insights for logistics managers.

Digital truck scales often come equipped with software that allows for easy data integration with enterprise resource planning (ERP) systems, inventory management systems, or transportation management systems (TMS). This integration enhances operational efficiency by automating data collection and analysis, reducing paperwork, and streamlining processes. Additionally, many digital scales offer remote monitoring capabilities, enabling managers to access weight data from anywhere, further enhancing the flexibility and control of operations.

4. Durability and Low Maintenance

Digital truck scales typically feature user-friendly interfaces that simplify the weighing process. While analog scales often require specialized knowledge or training to read accurately, digital scales use intuitive displays that present weight information clearly and concisely. These displays can include touchscreens or simple numerical readouts, making it easy for operators to view and record weight data.

Furthermore, many digital truck scales are designed with advanced features, such as automatic tare functions (which subtract the weight of the truck itself from the total), multi-language support, and customizable weighing modes to accommodate different types of loads. These user-friendly features not only enhance the operator experience but also reduce the likelihood of mistakes during the weighing process.

1. Higher Precision and Accuracy

One of the most crucial benefits of digital truck scales is their enhanced precision and accuracy. Analog truck scales rely on mechanical systems, which are subject to wear and tear over time. As these mechanical components degrade, the accuracy of weight measurements can decrease, leading to potential miscalculations. This issue can be particularly problematic in industries like agriculture, mining, and logistics, where accurate weight measurement is crucial to compliance with legal weight limits and ensuring proper load distribution.

Digital scales, on the other hand, use electronic sensors and load cells to measure weight. These components are less prone to wear and can provide more consistent and precise readings. The digital nature of the measurement process allows for finer resolution, meaning that even slight changes in weight are detected and displayed with high accuracy. This level of precision is essential for preventing costly fines for overloading, ensuring safe transportation, and improving overall operational efficiency.

3. Ease of Use and User-Friendly Interfaces

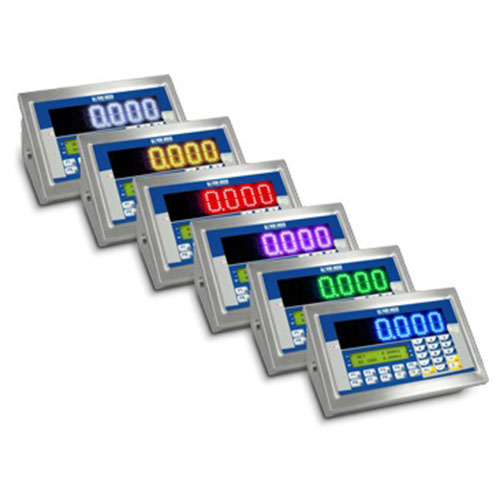

Digital truck scales typically feature user-friendly interfaces that simplify the weighing process. While analog scales often require specialized knowledge or training to read accurately, digital scales use intuitive displays that present weight information clearly and concisely. These displays can include touchscreens or simple numerical readouts, making it easy for operators to view and record weight data.

Furthermore, many digital truck scales are designed with advanced features, such as automatic tare functions (which subtract the weight of the truck itself from the total), multi-language support, and customizable weighing modes to accommodate different types of loads. These user-friendly features not only enhance the operator experience but also reduce the likelihood of mistakes during the weighing process.

5. Enhanced Security and Tamper-Resistance

Security is another area where digital truck scales outshine analog models. Analog scales can be more easily tampered with or manipulated, leading to inaccurate weight readings. This manipulation is particularly concerning in industries where weight data is crucial for compliance or billing purposes.

Digital scales offer enhanced security features, such as encrypted data transmission and tamper-resistant designs, to prevent unauthorized interference. Additionally, digital scales often provide a digital log or record of all weigh-ins, which can be useful for auditing purposes and ensuring the accuracy and integrity of the data. These security features help businesses avoid potential fraud, ensuring accurate weight measurements and maintaining trust with clients and regulatory agencies.

Conclusion

While analog truck scales have served the transportation industry for many years, digital truck scales offer numerous advantages that make them the preferred choice for modern operations. Their higher precision, real-time data capabilities, ease of use, durability, and enhanced security provide significant improvements over traditional analog models. As industries continue to prioritize efficiency, accuracy, and automation, digital truck scales are becoming an indispensable tool for streamlining operations and ensuring compliance with weight regulations.

WhatsApp us